Process ball valve vent options 3 internal ball vents 2 way valves purpose the internal vent equalizes pressure in the ball and body to that of the system protecting the valve from temperature induced overpressurization.

Self venting ball valve.

If that product off gasses it will build up pressure in the cavity area which could lead to a failure or other hazardous condition.

In particular this prevents the potential hazard if equipment is being maintained downstream of the isolation valve.

The internal vent equalizes pressure in the ball and valve body to the same as the system protecting the valve from damaging pressure build up.

How an internal vented ball valves work.

The key to ball valve performance is the sealing design regardless of whether the seats are made of metal plastic or other material.

Now that we understand how this pressure develops and how a vented ball valve counteracts this problem we can now understand the answer to the question of why is a vented ball valve needed.

Airy brass self venting ball valve f f t handle.

A range of trim material is available.

Vented ball for type 21 ball valve when a ball valve is closed product is trapped in the cavity of the ball.

A wide selection of nibco ball valves are available in bronze brass lead free carbon steel or stainless steel materials.

Gates globes check.

All valves pressure tested during production.

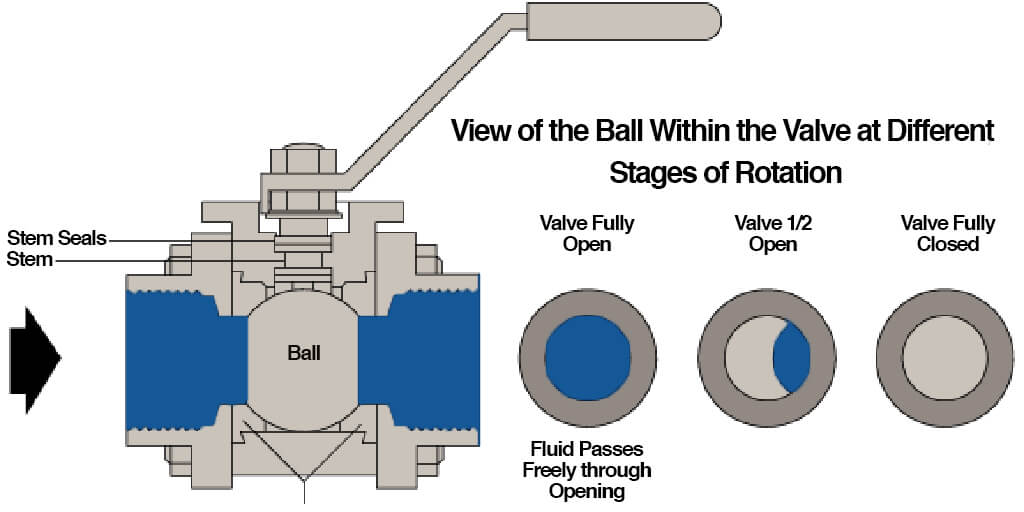

The ball has a vent that intersects the hollow part of the ball at a 90 angle.

A vented ball valve properly installed prevents both compressed air from reaching the air cylinder and vents or bleeds off any residual downstream pressure contained in the air lines supplied by the air cylinder.

Have a technical support question.

A floating ball valve is a ball valve with an unsupported ball other than the two seats it rests on so that the ball moves in the valve cavity to help seal off the line pressure.

The right ball valve for the job.

The flowserve worcester self venting valve has been designed to overcome the problems of stored energy that can be locked downstream in a process system once the valve has been closed.

Another important function of ball valve performance is the stem seal design.

There are no external vent ports.

Conical ptfe stem sealing system.

Backflow apollo engineering team sponsors uncc student project.

Self venting facility operates when valve is in the closed position.

This allows any.

A vented ball valve eliminates this unwanted pressure inside of the valve by venting the pressure through the vent on the ball.

See image the downstream vent equalizes pressure in the ball and body to that.

The ball contains a vent passage that intersects the ball orifice at a 90 angle.

The best way to remove the compressed air is by using a vented ball valve or residual pressure vent.